Following on from ourpredictions for green construction in 2020, Dodge Data & Analytics just released the findings of a landmark study on prefab and modular construction. The Prefabrication and Modular Construction 2020 SmartMarket Report (download below) was published with the support of Bradley Corp., the Modular Building Institute, Pinnacle Infotech, MCAA and Skender and takes a close look at the drivers, obstacles and benefits of building with prefab and modular construction, based on insight from architects, engineers and contractors already using and benefitting from them.

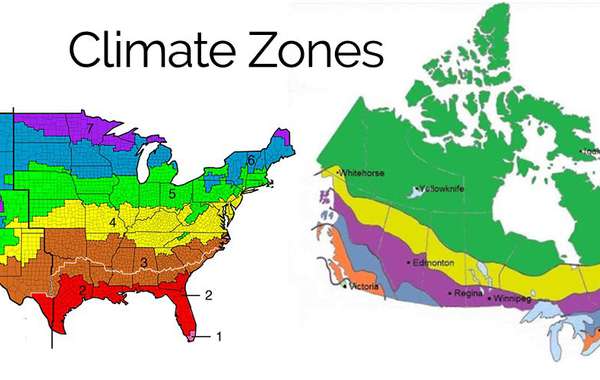

The report shows that architects, engineers and contractors who have built prefab and modular projects plan to significantly increase their use across the USA & Canada, especially for healthcare facilities, hotels and motels, multifamily projects, schools, college buildings and dormitories. We at Ecohome see significant interest in the prefab LEED, Passive House and Zero Net Energy ready kit homes sector in Quebec, Ontario and North Eastern US States such as New York, Vermont, Maine or New Hampshire.

What is driving building professionals to prefab & modular construction methods?

建筑行业的趋势,如更短的项目进度,可持续的施工实践和劳动力短缺,是预制和模块化组件建筑更广泛使用的几个驱动因素。This is driven by technology – such as building information modeling (BIM) assisted bycarbon footprint modelling information tools– which is enabling increased adoption of prefabrication.

In order to better understand the main drivers and obstacles for using prefab and modular building and the benefits achieved, the study focused on the architects, engineers and contractors who are already using them.

When it comes to methods already in use, the study shows that:

- Prefabricating single-trade assemblies (such as plumbing assemblies behind the wall in hospital rooms) is widely practiced, with 62% of respondents using prefabricated single-trade assemblies in the last three years.

- 48% of those doing modular are using panelized modular components (such as wall or floor panels).

- Use of each of these methods is also expected to increase in the next three years, with the percentage of those leveraging them on 10% or more of their projects nearly 15 points higher than present use.

However, the most interesting growth is expected in practices less widely used now:

- Prefabricated multi-trade assemblies, which involve the work of several trades combined together (such as a corridor rack in a hospital) will be used by 58% of those doing prefabrication in general—up dramatically from the 33% using this approach now.

- Equally dramatic growth is seen among those doing modular construction in the use of full volumetric approach, in which entire parts of buildings (such as bathrooms or hotel and hospital rooms) are delivered preconstructed to site and assembled together. A striking 61% expect to employ that method for at least 10% of their projects in the next three years, up from just 44% of those doing modular construction who currently report using this method.

“It comes as no surprise to us that more developers and GCs plan to use modular construction over the next few years,” said Tom Hardiman, Executive Director of the Modular Building Institute. “The lack of adequate housing and the shortage of skilled labor, coupled with chronic cost and schedule overruns are leading more people towards this process.”

The main benefits of prefab & modular builds?

About 90% of builders report that they achieve improved productivity, improved quality and more accurate project schedulingwhen incorporating prefab & modular methods compared to traditional stick-built construction.

80% or more also report that they see improved cost predictability, reduced construction waste and increased client satisfaction.

报告发现,改善项目进度、降低施工成本和改善建筑质量也是未来三年增加使用预制和模块化建筑的首要动机。

“Dodge’s research clearly shows that prefabrication and modular construction are providing significant improvements and efficiencies, and charting a new course in our industry,” says Jon Dommisse, Director of Strategy and Corporate Development for Bradley Corp. “Throughout our almost 100 years, Bradley has kept a close eye on emerging trends that impact our business and customers. We appreciate the partnership with Dodge in helping us examine innovative opportunities to hone our business strategy.”

Adoption of building information modeling (BIM) is accelerating prefab construction growth

The use of building information modeling (BIM) is also tied to the positive experience of these benefits, and to the growth of prefab and modular construction. Among those using BIM on the majority of their projects:

- 60% credit it with improving the schedule performance of their prefabricated or modular projects.

- 50% with improving budget performance.

“BIM improves the prefabrication and modular process by providing the means to accelerate the design early enough to take advantage of these approaches and then offering certainty during the entire process,” says Steve Jones, senior director of industry insights at Dodge Data and Analytics. “Having these tools helps enable the industry to invest more in the use of multi-trade assemblies and volumetric construction in particular, and may be contributing to the strong growth expected in these areas.”

被质疑者预计,使用预制和模块化建筑方法的最大增长将出现在医疗保健设施、旅馆和汽车旅馆、多户住宅和大学建筑和宿舍等设施完善的部门。然而,相当大的比例也预计低层办公室、K-12学校、公共建筑和商业仓储将经历越来越多的预制或模块化建筑项目。

Ecohome's thoughts on prefab & modular construction in relation to sustainable buildings

As the homes and buildings that we live and work in are having a devastating impact on the planet, any methods that can be effective in significantly reducing their impact on climate change have to be fully explored. Considering that:

- Buildings are the #1 source of climate pollution— with 39% of global emissions.

- Their construction and ongoing maintenance generate the largest share of the waste going into landfills.

- 到2050年,城市人口将翻一番,如果我们继续使用同样的建筑方法,浪费同样数量的材料和能源,我们的世界将无法承受这种日益增长的影响。

We at Ecohome feel that prefabricated and modular construction of homes and buildings is not only beneficial for all the reasons contained within this report, but it also permits trained professionals to recognize and leverage the opportunities in innovative materials and techniques to buildmore efficient, more affordable, longer lasting, more comfortable and low toxicity homesand buildings which waste significantly fewer building materials and create less waste during construction.

It's for this reason that we are promoting awareness of thehigh-efficiency and LEED, Passive House and Zero Net Energy ready prefab and modular home kits for salefrom the Ecohabitation organization in Quebec, includingaffordable prefab Rancher style eco homes herefor the Abri range..

As one of our founders Mike Reynolds says in the Ecohome trailer video onour YouTube channel (see below or here)

Comments (0)

Sign Up to Comment